MERQUEL®: The mercury emissions difference-maker

MERQUEL®: The mercury emissions difference-maker

Prior to the emergence of renewable energy sources, coal-fired power plants were a dominant force in local electricity generation. The transition to power generation via sustainable methods such as natural gas, solar and wind energy is crucial to protecting the health of our planet; yet for the time being, the steady increase in the global population – not to mention challenges ranging from climate change to geo-political instability – require traditional plants to continue to play a major role in the production of electricity.

Mercury emissions control

Due to an increased awareness of environmental hazards, regulations require coal-fired power plants to comply with strict emissions standards.

Coal combustion releases mercury, a toxin that is harmful to the environment and to human health. As a result, countries worldwide impose strict regulations on coal-fired power plants regarding mercury emission levels. To fully comply with regulations, power plants must reduce mercury emissions during coal combustion. The most cost-effective solution is mercury oxidization via halogen use.

The effectiveness of halogens as mercury oxidizers depends on numerous factors. Realizing the vast importance of mercury emissions control, ICL produces and supplies MERQUEL®, a patented portfolio of bromine-based solutions that are able to convert significant amounts of mercury into ionic species, which can then be removed via downstream pollution control methods. MERQUEL® solutions are tailored to a variety of variables and characteristics, including mercury coal content, power plant design, and more.

MERQUEL®: Unrivaled efficacy

MERQUEL® is a special solution compound applied directly in coal-fired power plants and incinerators. MERQUEL® exhibits extremely high mercury oxidization efficacy, in comparison to other halogens.

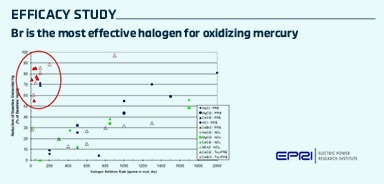

An efficacy study conducted by the Electric Power Research Institute (EPRI) determined that bromine is the most effective mercury oxidizing halogen. As seen in the graph below, calcium bromide reduced a higher percentage of elemental mercury in comparison to sodium chloride, hydrogen chloride, magnesium chloride and calcium chloride.

The many advantages of MERQUEL®

Mercury oxidization efficacy is MERQUEL's defining characteristic. Yet power stations that use MERQUEL® benefit from many additional advantages.

As far as mercury oxidization methods go, MERQUEL® is very simple to implement at production sites. Adding small amounts of MERQUEL® solution into the combustion chamber leads to highly effective mercury oxidization, even in cases where flue gases contain high concentrations of sulfur dioxide. Furthermore, small amount usage also promotes cost-effectiveness. When downstream pollution control devices operate effectively, MERQUEL® implementation can reach 90% mercury removal.

When MERQUEL® is applied to the power plant's ground coal feeder, well-operating wet and dry clean systems can easily scrub the converted ionic species from the flue gas stream. But MERQUEL® efficiency isn't limited to flue gas streams; the solution also enables scrubbers to remove significant mercury levels from other power plant outputs, including ash, wastewater, and different byproducts. Scrubbing the converted mercury from a variety of outputs prevents its emission into various natural ecosystems, transforming it into waste that can be treated according to waste treatment protocols.

Last but not least, ICL strives to ensure that MERQUEL® on-site delivery is both time and cost-effective. Our vast global distribution network enables us to transfer MERQUEL® products to various storage sites around the world. These storage sites are located in strategic locations – often within the proximity of coal-fired power stations.

Sustainable energy production

As long as coal-fired power plants continue to play a part in global energy production, effective mercury emissions control will be absolutely essential to the health of the planet and its inhabitants. For over 15 years, MERQUEL® use has actively promoted safer and cleaner traditional energy production in many corners of the world. Combining high-performance with strong global supply capabilities, MERQUEL® is a true difference maker.

We would love to hear from you!